Factory- Light Poles,

—Engineered for Coastal and Urban Areas

Your Trusted Street Light Pole Manufacturer

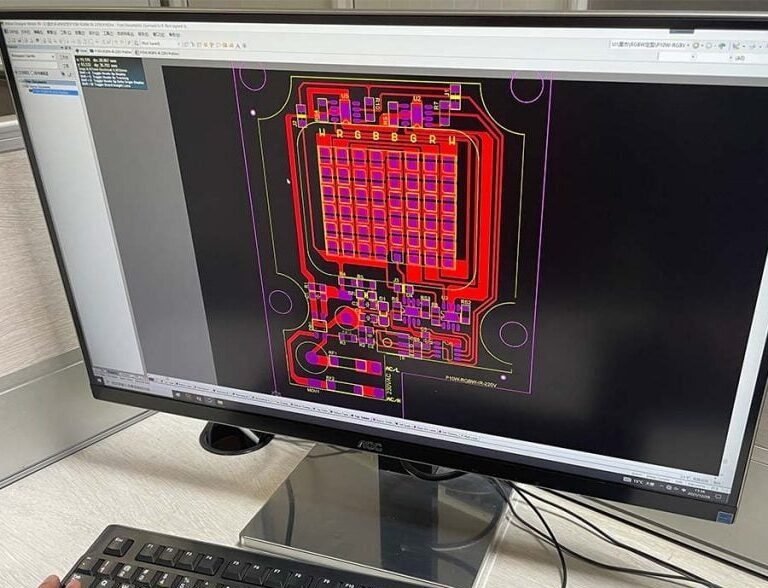

As a professional factory with over 18 years of experience, we provide OEM street light poles in any shape, size, or finish. From galvanized steel to powder-coated color finishes, our engineers handle everything — you get custom designs at no extra cost, delivered fast, and built to last.

As long as you need it, we can make it — in any material, shape, or color!

Solar Light Design

Customized solutions

Flexible Cooperation Models

Reliable After-Sales Support

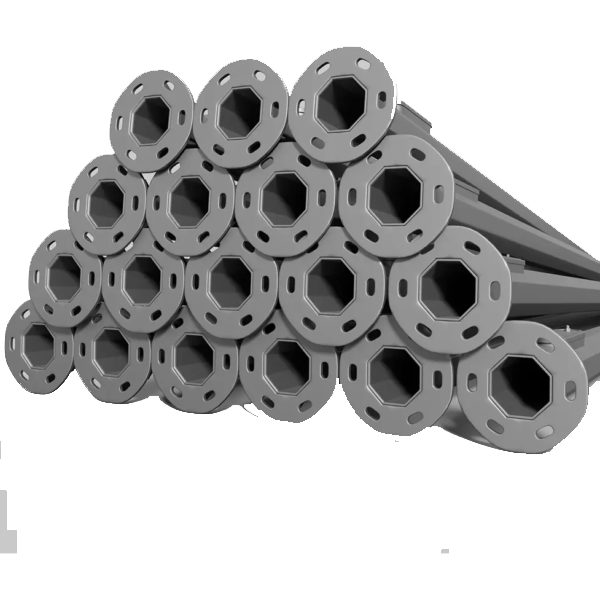

Aluminum Pole

Durable, lightweight, and corrosion-resistant aluminum poles ideal for outdoor lighting and signage solutions.

Features

- Lightweight – Easy to transport and install, reducing labor and transportation costs.

- Corrosion-Resistant – Withstands extreme weather conditions, making it ideal for outdoor environments.

- Versatile Designs – Available in various sizes and finishes, suitable for a wide range of applications.

Benefits

- Durability – Offers long-lasting performance with minimal maintenance.

- Eco-Friendly – Made from recyclable material, supporting environmental sustainability.

- Cost-Effective – Affordable upfront cost with low ongoing maintenance needs.

Applications

- Street Lighting – Commonly used to support street lamps and provide reliable illumination for roads.

- Security Lighting – Ideal for parking lots, outdoor venues, and security lighting solutions.

- Signage Support – Perfect for supporting billboards, traffic signals, and outdoor advertisements.

Let’s discuss the products you need.

Choose the Right Light Pole Material

| Attribute | Description |

|---|---|

| Best for | Urban roads, industrial zones |

| Pros | High strength, cost-effective, widely used |

| Cons | Requires galvanizing or coating to prevent rust |

| Attribute | Description |

|---|---|

| Best for | Coastal, humid, or polluted environments |

| Pros | Excellent corrosion resistance, long-lasting |

| Cons | Slightly higher cost than raw steel |

| Attribute | Description |

|---|---|

| Best for | Coastal projects, decorative lighting, premium urban zones |

| Pros | Lightweight, rustproof, maintenance-free |

| Cons | Higher cost than steel, less load-bearing strength |

| Attribute | Description |

|---|---|

| Best for | Projects requiring high durability and clean aesthetics |

| Pros | Excellent corrosion resistance, modern appearance |

| Cons | Most expensive material option |

How to Choose the Right Light Pole Height

The ideal light pole height depends on the lighting area, pole spacing, and application type. Here’s a general guide:

| Pole Height | Best For |

|---|---|

| 3–5 meters | Pathways, gardens, residential areas |

| 6–8 meters | Parking lots, urban roads, small streets |

| 9–12 meters | Highways, large open areas, wide roads |

| 12+ meters | Airports, stadiums, industrial zones |

Tips:

- Use lower poles for areas needing soft or pedestrian-level lighting.

- Taller poles provide wider coverage but require higher power LEDs.

- Always match height with pole spacing and luminaire type for optimal results.

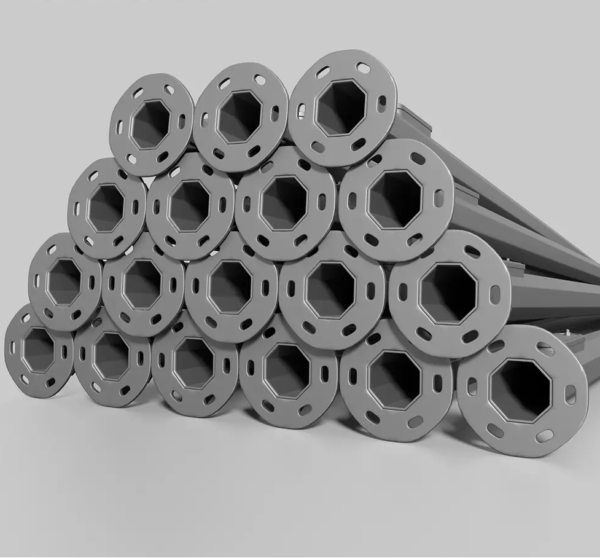

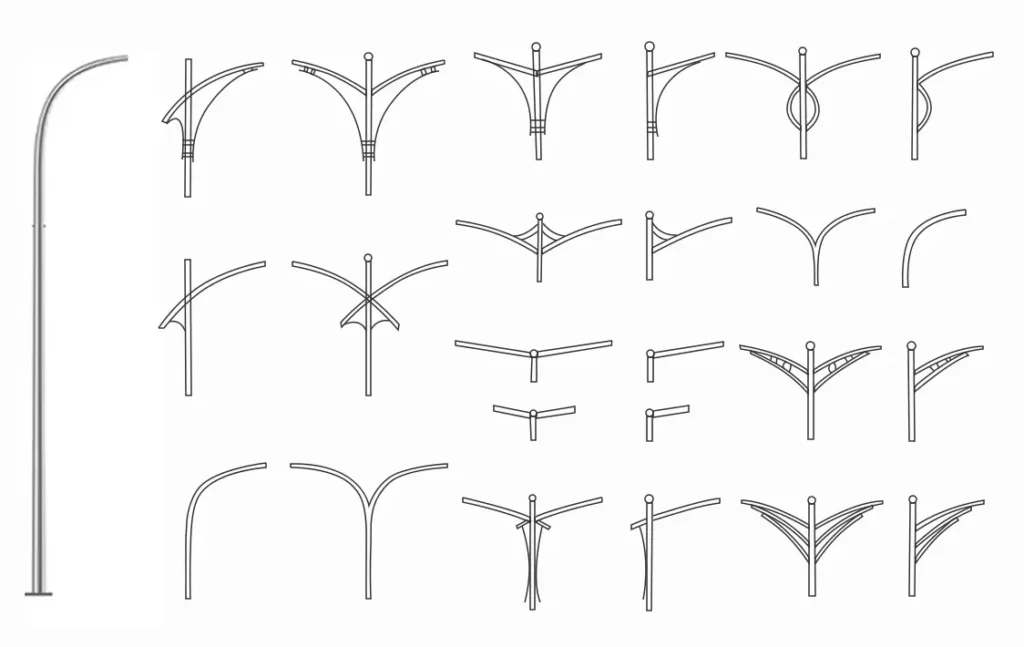

What are the types of light pole shapes?

Light poles come in various shapes to meet different structural, aesthetic, and installation needs. Here are the most common types:

| Shape | Description |

|---|---|

| Round | Smooth cylindrical design, simple appearance, easy to manufacture |

| Tapered Round | Narrower at the top, helps reduce wind resistance and material weight |

| Octagonal | Eight-sided pole, widely used for its strength and modern look |

| Conical | Elegant taper from bottom to top, commonly used in urban or decorative projects |

| Square | Four flat sides, often used for decorative or architectural lighting poles |

| Polygonal | Multi-sided design (e.g., 12 or 16 sides), balances strength and aesthetics |

How to Install a Light Pole

Installing our street light poles is simple and efficient. Whether for solar or grid-powered systems, follow these 6 basic steps:

1.Prepare the foundation

Dig a pit (1.2–2.0m deep) and place anchor bolts in position using a template.

2.Pour concrete

Use C30-grade concrete and ensure anchor bolts are vertically aligned. Let it cure for 3–7 days.

3.Assemble components

Attach the light head, bracket, solar panel, and controller (if needed) before raising the pole.

4.Erect the pole

Align the flange with anchor bolts, tighten nuts securely, and ensure the pole stands straight.

5.Connect wiring

Use waterproof connectors. For solar: connect panel, battery, and light. For AC: link to power supply.

6.Final check

Test the light, check verticality, and clean the solar panel surface (if applicable).

| Item | Specification |

|---|---|

| Foundation Depth | 1.2–2.0 meters |

| Concrete Type | C30 standard |

| Bolt Exposure Height | 100–150 mm above ground |

| Installation Time | 30–60 minutes per pole |

| Assistance Provided | Drawings, diagrams, videos ✅ |

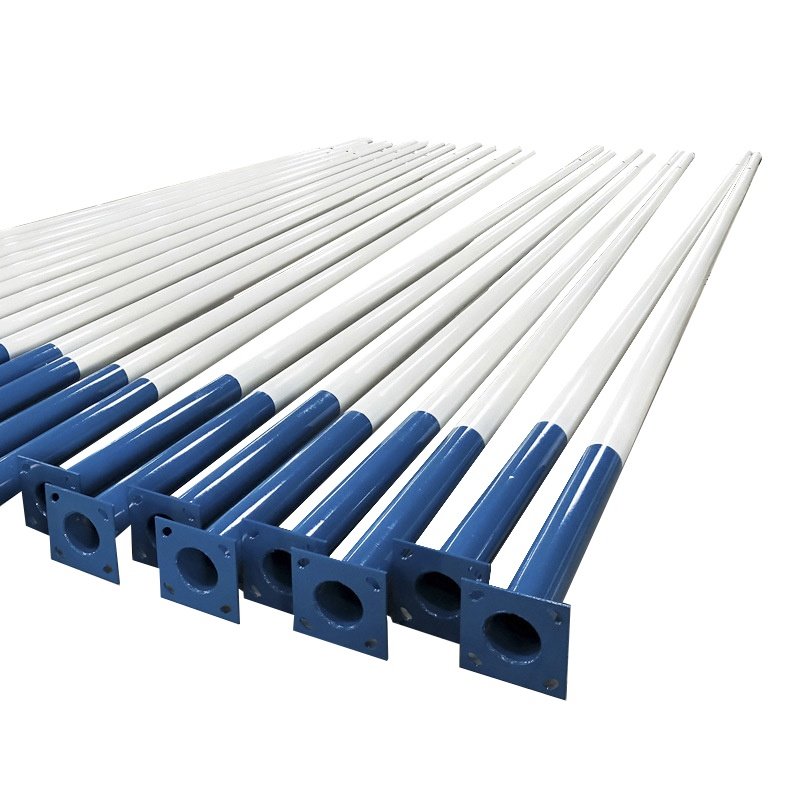

Surface Treatment Options for Street Light Poles

To ensure long-term durability, weather resistance, and a professional appearance, we offer multiple surface treatment options for our steel and aluminum street light poles. Each option is selected based on the installation environment and project requirements:

🔹 Hot-Dip Galvanizing

A full immersion process where the pole is coated inside and out with a thick layer of zinc.

Features:

Excellent corrosion resistance

Ideal for harsh environments such as coastal or industrial zones

Lifespan up to 20–25 years with minimal maintenance

Recommended for: Highways, seaports, bridges, humid and rainy areas

🔹 Powder Coating (on Galvanized Surface)

An electrostatic coating process applied over galvanized poles, offering both protection and aesthetics.

Features:

UV-resistant and anti-fade

Available in various colors (gray, white, black, green, etc.)

Enhances visual appeal and matches urban design

Recommended for: City roads, residential areas, parks, commercial spaces

🔹 Hot-Dip Galvanizing + Powder Coating (Dual Protection)

Combines deep rust protection with a decorative color layer.

Features:

Maximum durability and stylish appearance

Resists salt spray, UV, and acid rain

Excellent for long-term urban infrastructure

Recommended for: Municipal lighting, premium projects, smart pole systems

🔹 Spray Painting

A budget-friendly painting option with basic anti-rust protection.

Features:

Lower initial cost

Requires regular repainting in outdoor use

Recommended for: Temporary lighting, rural roads, budget-limited projects

🔹 Anodizing (For Aluminum Poles Only)

Electrochemical treatment that strengthens the natural oxide layer on aluminum surfaces.

Features:

Metallic, modern appearance

High resistance to oxidation and discoloration

Recommended for: Decorative poles in parks, resorts, or modern architectural areas

How Wind-Resistant Are the Light Poles

Yes — our street light poles are specifically engineered to perform reliably even in regions with strong and frequent winds. We follow strict national and international standards to ensure safety and durability.

✅ Standard Wind Resistance

Our poles are designed based on GB/T 1591 and EN 40 standards and are capable of withstanding wind speeds up to:

117 km/h (Level 12 typhoon) for standard designs

140+ km/h (Level 13–14 winds) for enhanced models with reinforced structures

Each pole’s wind load resistance is calculated based on its height, material thickness, arm length, and fixture load, ensuring optimal structural safety.

✅ Reinforced Options for High-Wind Regions

For areas frequently affected by storms, typhoons, or desert winds, we offer:

Thicker pole walls (up to 6mm)

Larger and thicker flange plates

Optimized taper geometry for better stress distribution

Custom base designs with deeper foundations and wider anchor spacing

These options significantly improve the pole’s stability and fatigue resistance over time.

✅ Foundation & Installation Matter

A pole’s safety doesn’t depend on structure alone — we also provide:

Foundation design drawings with correct depth and bolt sizing

Anchor bolt kits tailored to pole size and wind class

Internal cabling and anti-vibration designs for smart pole systems

✅ Documentation Support

For government, highway, or EPC projects, we can provide:

Wind load structural calculations

Pole strength simulation reports (FEA available)

Installation instructions with regional wind zoning data

📌 Recommended Applications for High-Wind Areas:

Coastal roads and seaports

Desert highways or elevated terrain

Bridges, islands, and typhoon-prone regions

Industrial zones with open and exposed environments

The ULTIMATE Guide to Sourcing Solar Lights in China

- Totally free and full of resources

- Save your ton of time to make a decision

- A must-have checklist for sourcing

- Written by a experienced engineer