Choosing the wrong type of light pole isn’t just a technical mistake—it can derail your entire project. Structural failure, code violations, and huge maintenance costs are just the beginning.

Your light pole must match the environment, wind load, fixture type, and local codes. Picking the wrong type leads to project delays, legal issues, and safety hazards.

This guide will help you avoid those mistakes by showing how to choose the right light pole for your use case—from parking lots to coastal roads.

Why Light Pole Type Is Critical to Project Success

It’s tempting to go for the cheapest or most available pole. But the wrong choice can end up costing more than the project itself.

Light pole type affects safety, compliance, lifespan, and lighting quality. Choosing the wrong one creates serious risks.

-

Safety, Compliance, and Durability Risks

A pole not rated for local wind zones can collapse. Poor materials corrode in coastal climates. If you skip these factors, the pole will fail—sometimes catastrophically. -

Impact on Lighting Performance and Maintenance

A flexible pole might cause fixtures to shake, distorting light patterns. Some poles can’t support heavy luminaires or solar panels. Long-term maintenance shoots up when you mismatch pole and environment. -

Premature Failure or Code Violations

Using an anchor base in sandy soil without proper depth leads to leaning or cracks. Using non-rated poles in hurricane-prone areas can trigger code fines or replacement orders.

Types of Light Poles and Their Best Use Cases

Each pole type serves a different purpose. Understanding their pros and cons will help you match them to the right environment.

Not all poles are created equal. Each material has specific strengths, weaknesses, and ideal conditions.

-

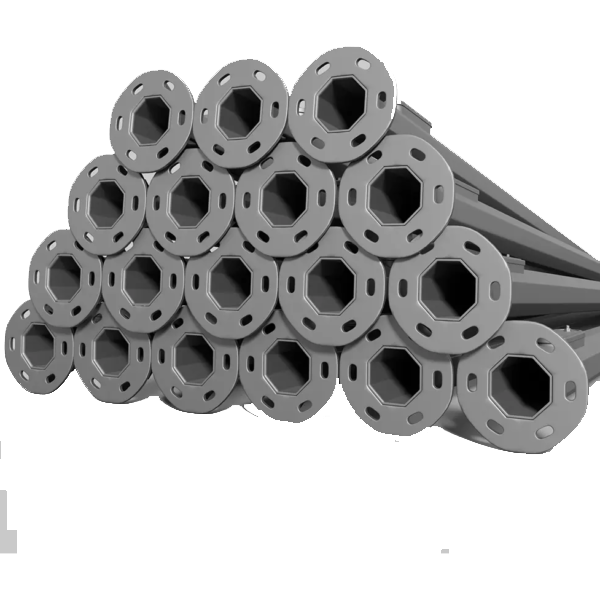

Steel Light Poles

- High strength, ideal for highways, stadiums, and commercial parking lots

- Galvanized steel resists corrosion better than powder-coated steel

- Powder-coating offers aesthetic options but needs more surface prep

-

Aluminum Light Poles

- Lightweight and corrosion-resistant

- Perfect for coastal areas, pedestrian walkways, and decorative streetscapes

- Easier to install but less load-bearing than steel

-

Concrete Light Poles

- Stable and vibration-resistant

- Excellent in windy or high-traffic zones like expressways

- Heavy and harder to transport or install; best for permanent setups

-

Fiberglass/Composite Poles

- Non-conductive, maintenance-free

- Great for utility zones, wet environments, or areas near power lines

- Not ideal for heavy fixtures or high wind exposure

-

Wooden Light Poles

- Traditional, natural aesthetic

- Mostly used for rural roads, telephone lines, or low-budget utility work

- Susceptible to termites, decay, and weathering if untreated

How to Choose the Right Light Pole for Your Project

Picking the right type is more than selecting material. You must also consider climate, soil, fixture load, and code compliance.

Match pole type with your site’s real-world conditions—don’t rely on guesswork or supplier defaults.

-

Match Pole Type with Environmental Conditions

- High wind zones: Use steel or concrete

- Coastal areas: Choose aluminum or composite

- Wet soil: Use direct burial poles with sealed bases

-

Consider Height and Fixture Compatibility

- Taller poles need stronger bases and stiffer materials

- Heavier fixtures need stronger poles

- Solar panels or double-arm fixtures increase EPA (effective projected area), which changes what the pole can support

-

Check Local Codes and Lighting Standards

- Most municipalities have rules about height, wind rating, and setbacks

- Skipping code compliance can mean red tags or re-installation costs

-

Evaluate Installation and Long-Term Maintenance Needs

- Steel poles need repainting or galvanizing

- Concrete poles need deeper, reinforced footings

- Composite poles need almost no maintenance but can crack under impact

Common Mistakes When Choosing a Light Pole

The most costly failures come from ignoring small but critical technical requirements.

Avoid these common mistakes to protect your budget and your timeline.

-

Ignoring Wind Load and Pole Flexibility

- Every region has a wind map. Poles must match it or they’ll bend—or worse, snap.

- Use wind-rated poles based on EPA calculations for fixtures, arms, and signs.

-

Choosing the Wrong Base Type

- Direct burial is cheaper but needs solid soil.

- Anchor base poles are better for rocky or soft soils—but they need precise bolt layouts.

-

Overlooking Corrosion Resistance

- Inland poles can use powder-coated steel.

- Near saltwater, use anodized aluminum or galvanized steel only.

- Forgetting this will lead to early rust-out, especially at the base.

-

Misjudging Weight Support for Fixtures

- Some fixtures need poles with reinforced upper shafts.

- Adding banners, cameras, or solar panels increases EPA load.

- If not accounted for, the pole will tilt or fail.

Cost vs Performance: What You Should Really Consider

Low-cost poles often end up being the most expensive decision you can make.

Think about long-term performance, not just the invoice. Fewer replacements mean more savings.

-

Upfront Cost vs Lifecycle Cost

- Steel may cost more upfront, but lasts 20+ years with galvanizing.

- Cheap poles without proper treatment rust, tilt, or break in <5 years.

-

Repair, Replacement, and Downtime Impacts

- Replacing a pole means labor, rewiring, and traffic management

- A failed pole also risks injury or lawsuits

- Use stronger poles at critical sites like highways and parking lots

-

Warranty and Certification Considerations

- Always ask for wind load certification

- Check for ISO, ASTM, or UL compliance

- Longer warranties (10–20 years) indicate better durability and fewer problems

FAQs About Light Pole Types?

What is the most durable type of light pole?

Galvanized steel poles with reinforced bases and proper coatings last the longest.

Can aluminum poles be used in high-wind areas?

Yes, but only if wind load and EPA ratings are within limits. Use shorter heights or smaller fixtures.

How do I know if a pole is wind-rated for my zone?

Check the pole’s EPA rating and compare it with your local wind speed zone on ASCE 7 maps or municipal data.

What's the best light pole for parking lots or streets?

Steel poles are standard for streets and lots due to strength. Use aluminum for coastal or decorative zones.

Conclusion

The wrong pole type can lead to failure, fines, and full project do-overs. But the right one saves time, money, and lives.

Choose based on your site’s environment, not just price. Always verify compliance, fixture match, and wind resistance. When in doubt, ask an expert.